Look ma - no fan!

2002

Electric Engine Fan Conversion

Want an easy extra 5 horsepower, 2 or 3 more MPG, less noise, and smoother running? Then get rid of the engine-driven cooling fan! A compromise between overheating at idle and wasting power at higher engine speeds, the only thing the '02's stock engine-driven fan has going for it is that it is reliable.

A thermostatically-controlled electric engine fan will give better cooling at idle, more power at high rpms, smoother and quieter operation overall, faster revving, longer water pump bearing life, and slightly quicker engine warmup. On an '02, removing the engine-driven fan will reduce the likelyhood and severity of radiator damage should your motor shift forward a bit, too... The one major caveat is that an electric engine fan will substantially increase the draw on the wimpy '02 electrical system - the fan I used draws about 27A when first starting and 18A continuous current. So, while not absolutely required, this mod is best done in conjunction with an alternator upgrade.

Here's what I did to install an electric fan - as usual, this is not a step-by-step how-to but more of a sharing of ideas. Adopt them at your peril...

The

Fan

There are many aftermarket

and junkyard/OE fans that can work in this application. Whatever you find, it

will have to be a "pusher" type of fan that is designed to sit in

front of the radiator since there is very little room between the engine water

pump pulley and the back of the rad.

I used a salvaged E21 320i auxiliary fan (as found on A/C equipped cars). It is a heavy-duty, OE-quality Bosch part and has the major bonus of coming with some nearly-ideal rubber-isolated mounting brackets. It is about 13" in diameter which is just the right size for the '02 rad.

The bare 320i auxiliary

cooling fan. This is the

side that faces the rad. The upper brackets have

already been re-worked.

Fan is mounted as close

to the rad as possible.

Most "universal" aftermarket fans come with hardware that mounts the fan directly to the radiator core. While convenient, this is usually very hard on the rad and can lead to core leaks. A much better way is to mount the fan to the chassis which is why the 320i fan is a good choice. Other than needing to re-work the upper brackets, this fan fits almost like it was originally designed for an '02 - the fan and shroud make no contact with the rad but are still held very close to the radiator core so air is not spilled away. The rubber isolators in the brackets reduce fan noise in the cabin.

I had to use short spacers so that the brackets could neatly clear the edges of the opening in the radiator support bulkhead. The rubber spacers were quickly made up of slices of fuel line inside slices of heater hose.

The fan's upper brackets were bent

to bring the mounting bolt hole forward on the car and to lower the fan about

1" so it is not eclipsed by the bulkhead.

Fan Control

The whole point of this

modification is that the fan does not run all the time, so some kind of thermostatic

control is required. Electronic or electro-mechanical engine fan thermostats

are available commercially, of course, but I went home-brew 'cause I had me

an idea...

I noticed that the large drain plug on the left side of a late-style '02 rad just happens to have a 14mm thread that matches the '02's temperature gauge sender and is in the perfect spot.

Temperature sender installed in rad tank.

Unfortunately, most '02 rads have a smaller

drain plug in the rear of the bottom tank

that won't work for this sensor.

This sensor location is ideal because the bottom of the rad is exactly where you want to measure the temperature for controlling the fan. Only when the coolant exiting the rad (out the bottom hose) gets too close to the engine operating temperature do you need to turn on the radiator fan. If you put the fan control sensor in the radiator's upper hose or on the engine's coolant manifold (both places where the coolant is always near the engine operating temp), you'd have to set the on-point such that the engine will either have to start to overheat before the fan will be triggered, or the fan will run almost all the time.

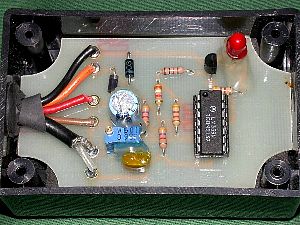

To be able to make use of a spare '02 temp gauge sender and because I had a full electronic junk bin and more time than money, I custom designed a simple adjustable controller to trigger a standard automotive 40A relay. Though this is a very simple circuit, for fun I taught myself to use Eagle CAD software to create the schematic and lay out the printed circuit board that I then etched myself.

The innards of the fan control

unit.

Power

Supply

Because the fan draws so much power,

it will need as direct a connection as possible to the battery and suitably-thick

conductors. On my installation, the fan motor power comes directly from the

main power distribution block (because I have relocated

the battery) through an inline fuse (30A) in a weatherproof holder to the

relay. Wiring is 4 gauge and the relay's normally-open contacts are rated at

40A. Power for the control module is taken from the horn relay circuit so that

the fan switches off with the ignition but will run if the key is left in the

accessory position and the radiator is hot. The fan's negative power wire is

grounded to the chassis, near the fan on the front bulkhead.

The fan control unit is

mounted where

the voltage regulator used to be. Fan relay is closest to it.

I'm not exactly thrilled with the Feng-Shui of this wiring, but it is functional and has proven reliable. One day, I'll find a small accessory fuse panel and will make a nice looking mounting bar for the extra relays - and use all the same style.

Results

Six months old as I write this in

November 2004, the 320i fan conversion is performing very well. With the controller

adjusted to switch the fan on at approximately 65ºC, I was amazed to discover

that on a 15ºC day, the fan is almost never needed. Only after idling for

30 seconds or so will it come on, and then not for long. Once the car is moving

at 20mph or more, the fan is always off. While the fan is quite audible from

outside the car, noise is not an issue. With my windows down I can sometimes

hear it running if I am waiting at a light but usually the traffic noises drown

it out - often the only clue it is running is the slight drop in idle speed

as it comes on. The engine is now noticably less noisy, feels a bit smoother,

and seems slightly more willing to rev. Even when sitting in gridlock on a sweltering

35ºC summer day, the temperature gauge has remained totally within it's

normal (for my car) range of one needle-width above and below 3 o'clock (with

an 80ºC engine t-stat). I *think* I have seen about 2.5mpg better fuel

economy, too. ;-)

This

site is best viewed at 1024x768 resolution.

This web site and all images Copyright © 2004

by Zenon Holtz, all rights reserved.